Asembly of Magni 6 Mini

This guide provides clear, step-by-step instructions for assembling the Magni 6 Mini robot.

Note

If any parts are missing, refer to the Magni BOM for ordering details. For unavailable items, contact Ubiquity Robotics support.

[TODO: We will add the link to the Magni 6 BOM order details here.]

Build Requirements

Before starting, ensure all required components are available. The tables below list the Magni 6 Mini Bill of Materials (BOM). Use specified BOM items to avoid assembly issues, though simiral components may be substituted if necessary.

Screws BOM |

|

|---|---|

BOLT M2,5x14 ((8.8) Zn) ISO 7380 |

5 |

BOLT M2,5x10 ((8.8) Zn) ISO 7380 |

2 |

BOLT M2,5x8 ((8.8) Zn) ISO 7380 |

17 |

BOLT M2x14 ((8.8) Zn) ISO 7380 |

2 |

BOLT M2x5 ((8.8) Zn) ISO 7380 |

8 |

BOLT M2,5x5 ((8.8) Zn) ISO 7380 |

2 |

BOLT M4x8 ISO 7380 |

10 |

WASHER 2,7 (Zn) DIN 125 |

22 |

WASHER 4,3 (Zn) DIN 125 |

6 |

SPACER L=12 F_M2,5 |

4 |

PCB PUSH PIN WITH SPRING |

2 |

Other BOM |

|

|---|---|

BASIC |

1 |

TOP COVER |

1 |

FRONT COVER |

1 |

FIREWALL |

1 |

BATTERY HOLDER |

1 |

HEAT SINK |

1 |

MOTOR WHEEL |

2 |

CAMERA MODULE 3 V8 |

2 |

5.5 x 2.1 mm DC POWER CHARGER |

1 |

SINGLE BALL ROLLER BEARING |

1 |

RUBBER TYRE |

2 |

ON/OFF ROCKER SWITCH |

1 |

LIDAR |

1 |

RASPBERRY 5 |

1 |

MOTOR BOARD |

1 |

BATTERY |

2 |

SONAR |

15 |

COVER CAP |

16 |

LIDAR |

1 |

RUBBER PAD |

1 |

MOTOR WHEEL |

2 |

RUBBER SOCKET |

1 |

Assembly Intructions

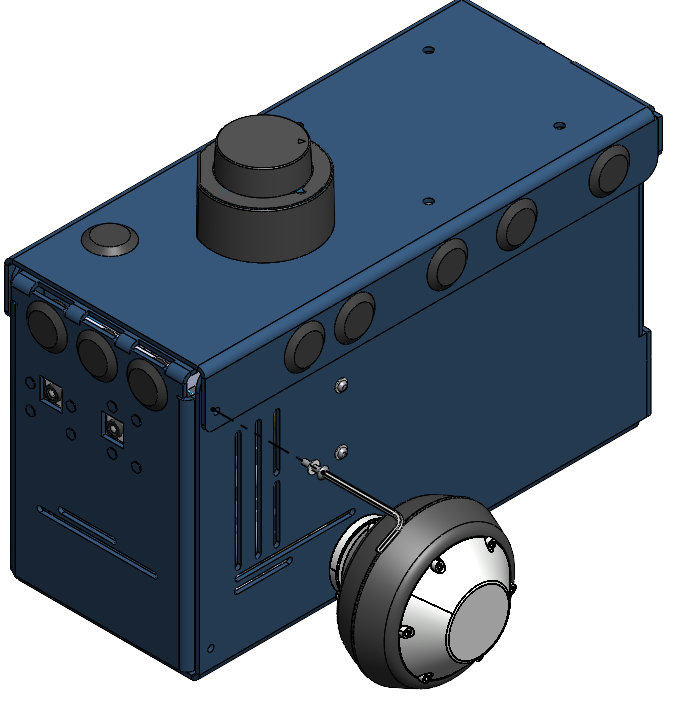

Final Assembly Preview

Step-by-Step Assembly

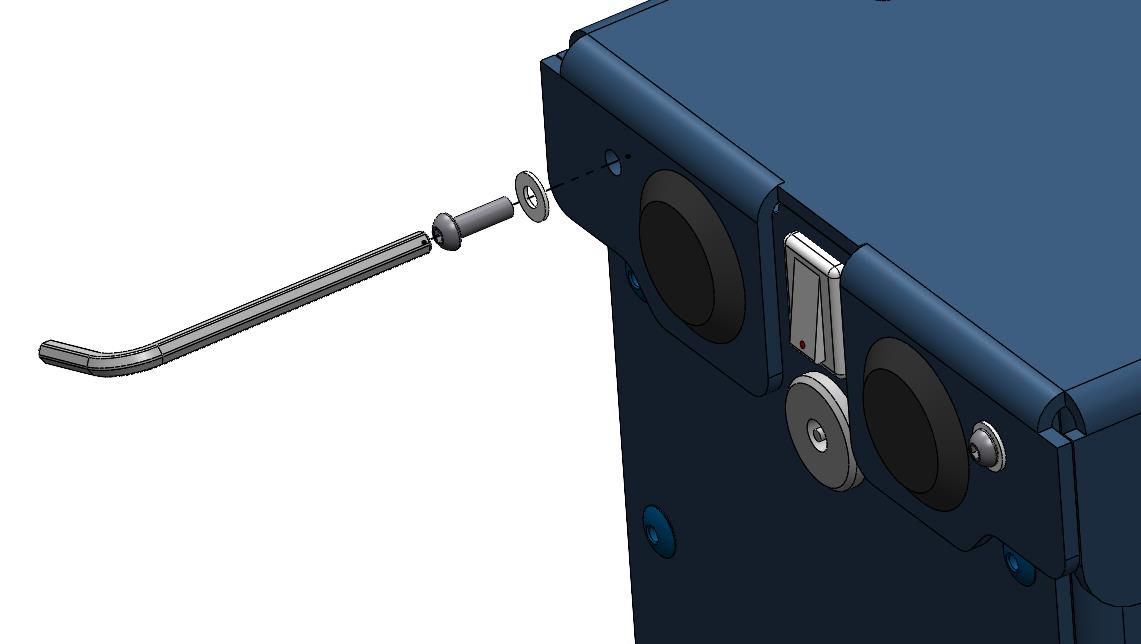

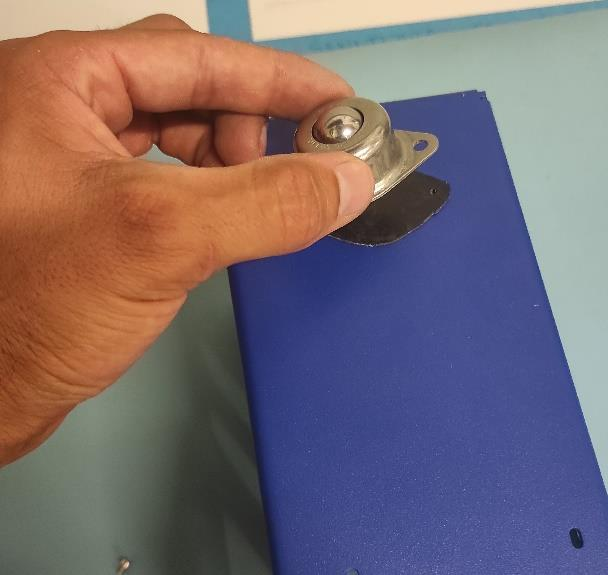

Attach Roller Bearing to Base

Secure the SINGLE BALL ROLLER BEARING and RUBBER PAD to the BASIC sheet metal part using 2x BOLT M2x5 (8.8) Zn) ISO 7380. Tigthen genrly with a hex key using two-finger pressure to avoid overtightning.

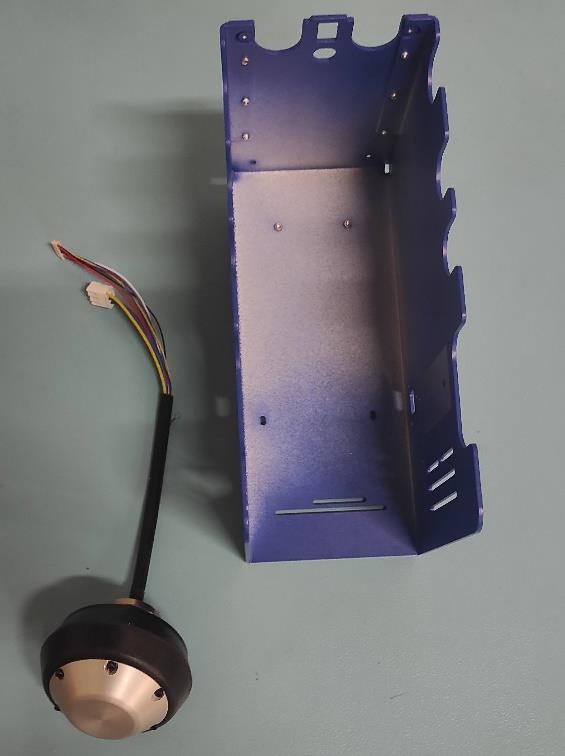

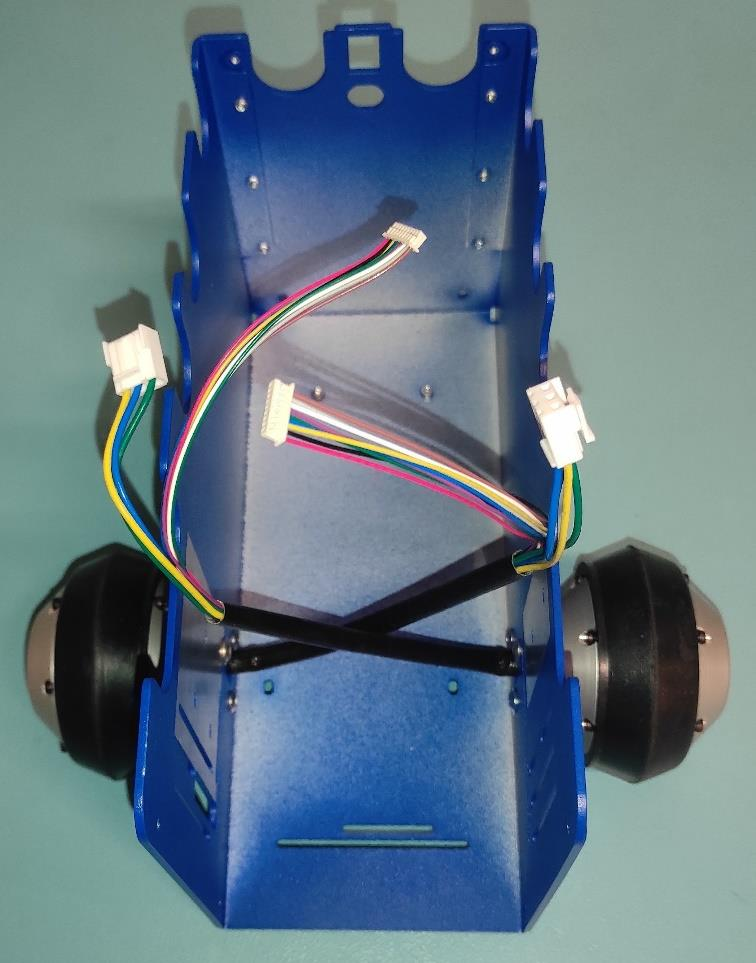

Prepare Motor Wheels

Take MOTOR WHEEL and BASE.

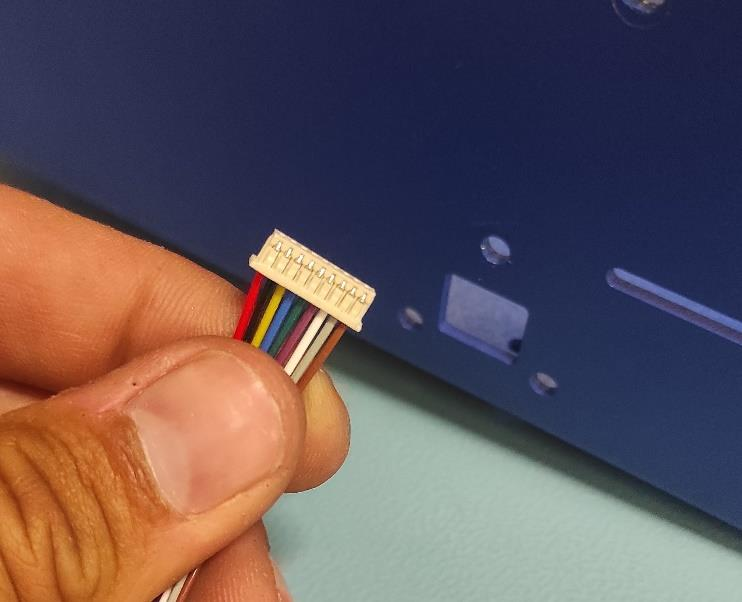

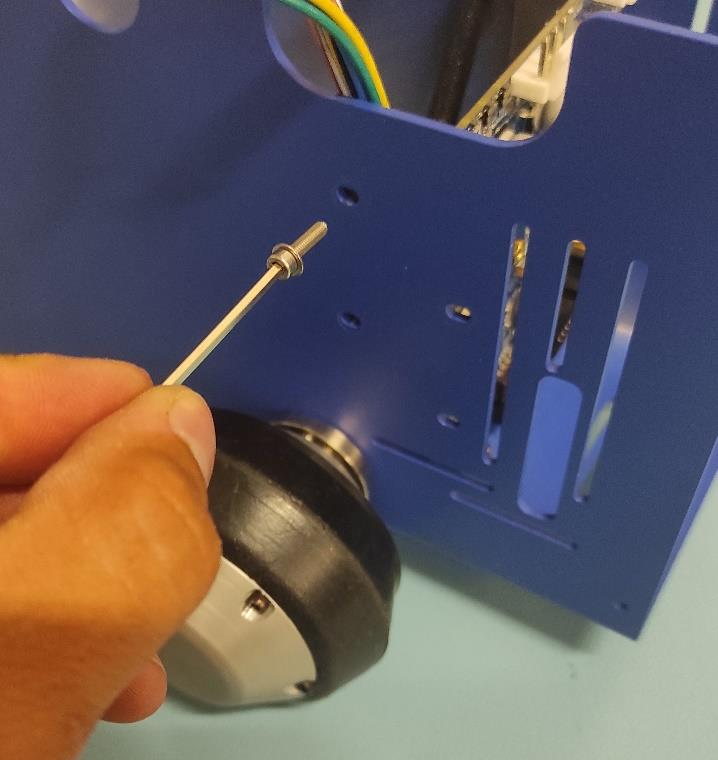

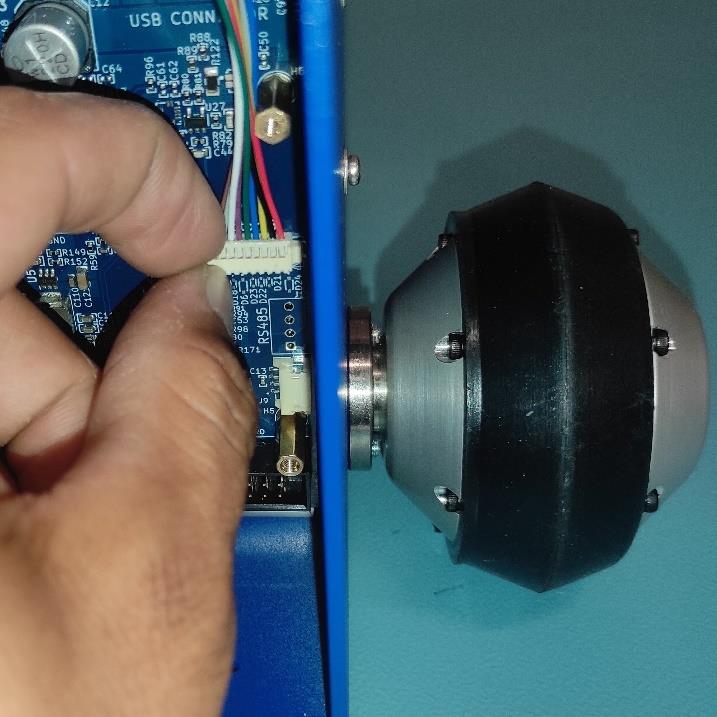

Insert Motor Wheel Connector

Slide the small MOTOR WHEEL connector diagonally through the base opening.

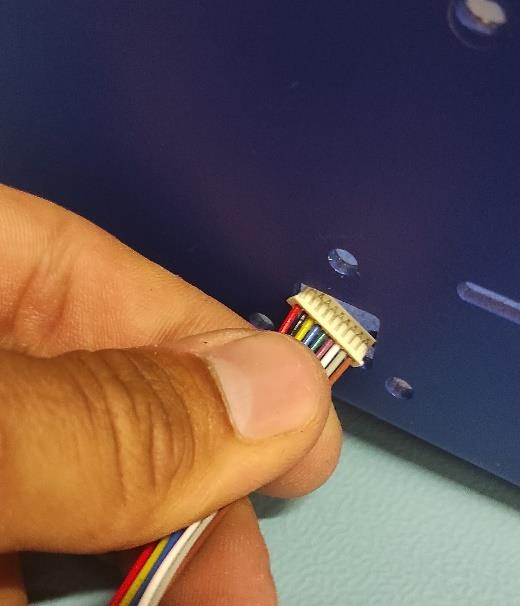

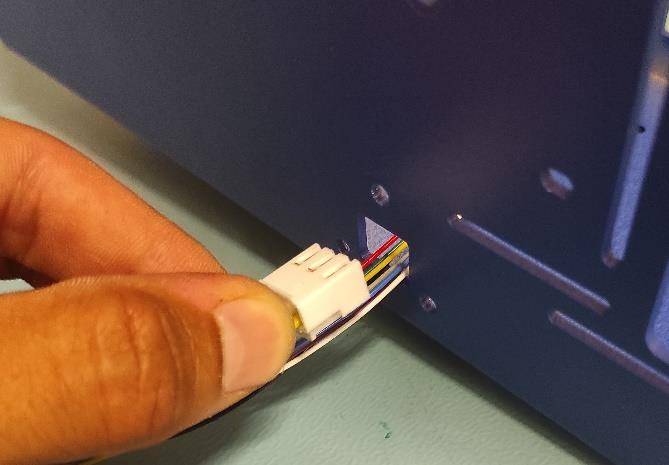

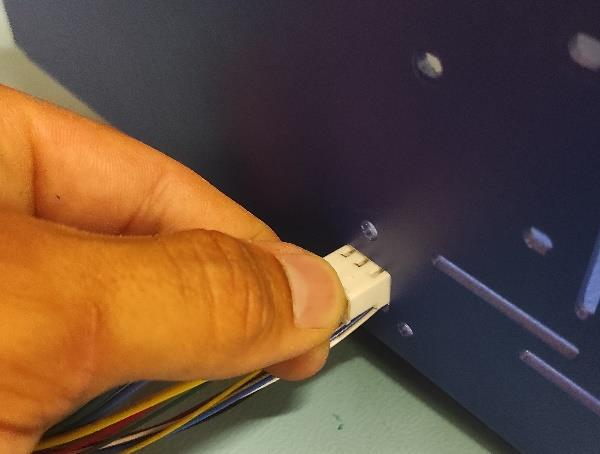

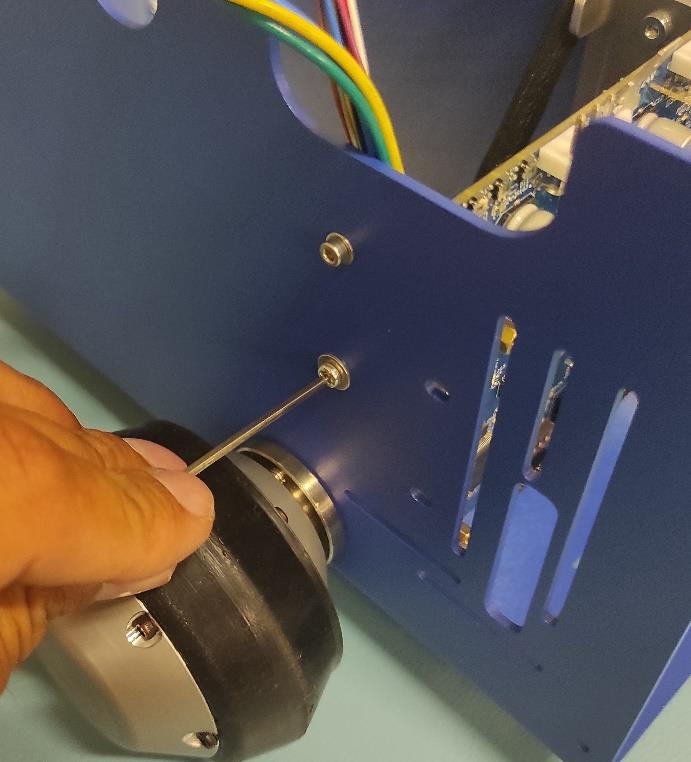

Insert Second Connector

Push the second MOTOR WHEEL connector through the opening, ensure the orientation is correct.

Secure Motor Wheel

Use 3x BOLT M4x8 ISO 7380. Thread each bolt lightly by hand. Tilt the base so the wheel faces up, then the second and third bolts.

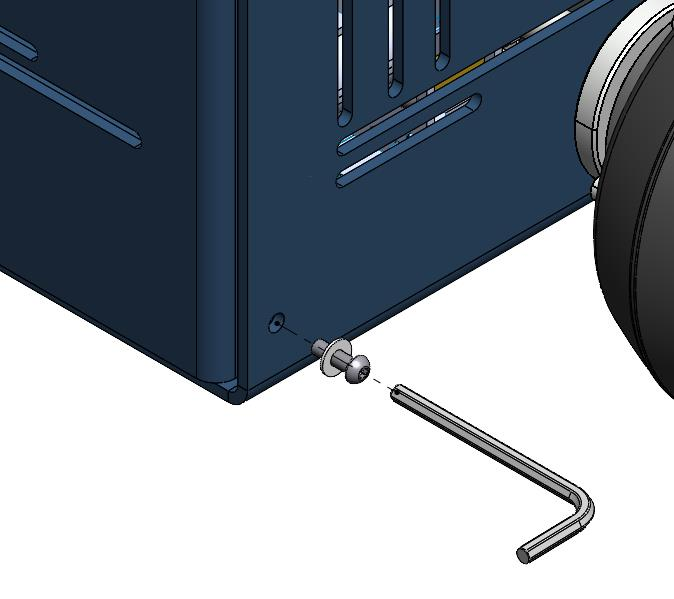

Tighten Motor Wheel Bolts

Fully tighten all three bolts with an Allen key.

Repeat for the Other Side

Follow steps 2-6 for the second MOTOR WHEEL.

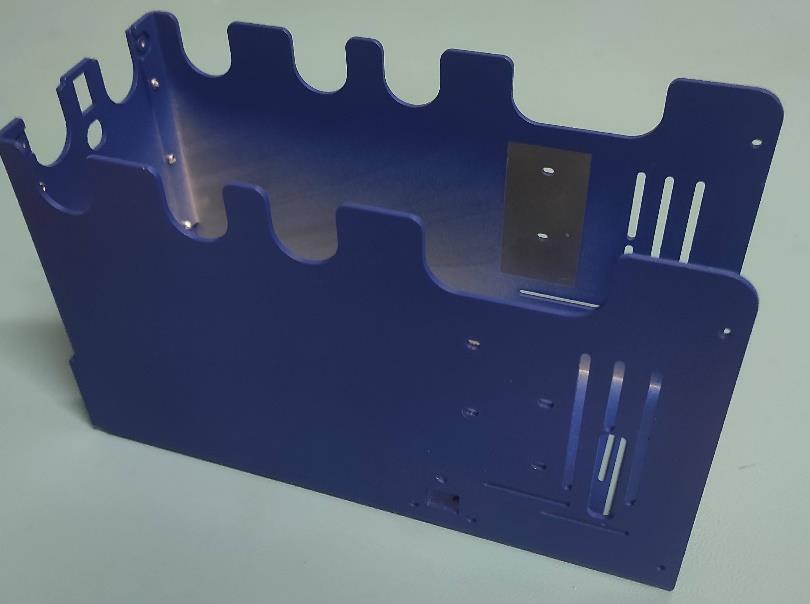

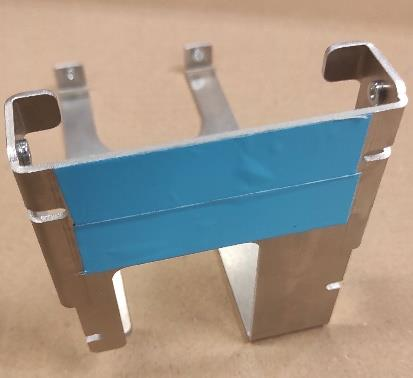

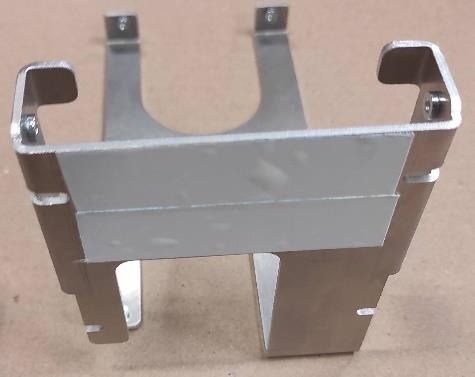

Prepare Firewall

Cut two 70x20 mm strips of double-sided thermally conductive tape. Apply to FIREWALL and remvoe protective film.

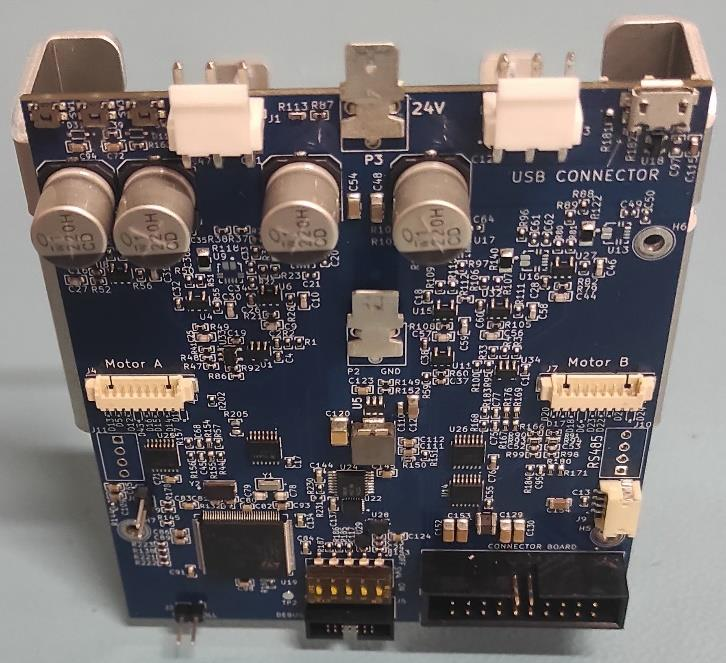

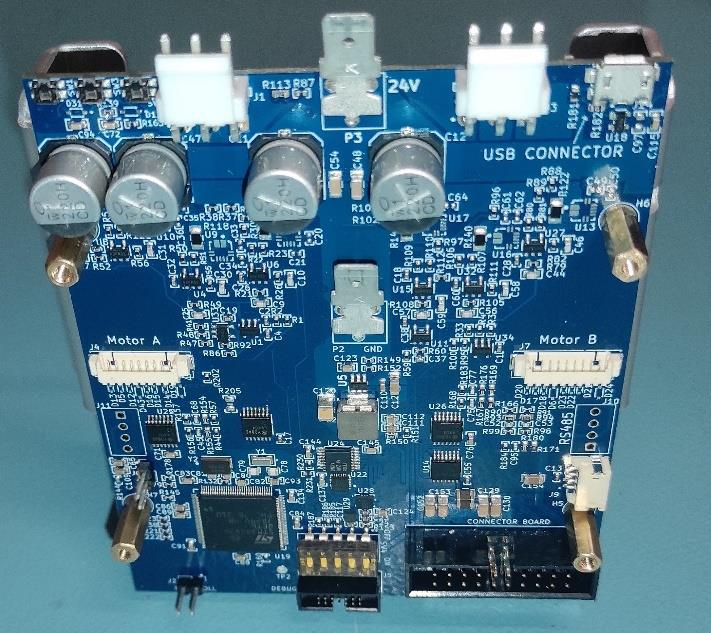

Mount Motor Controller Board

Press the MOTOR BOARD onto the tape, aligning mounting holes with FIREWALL slots.

Secure Firewall to PCB

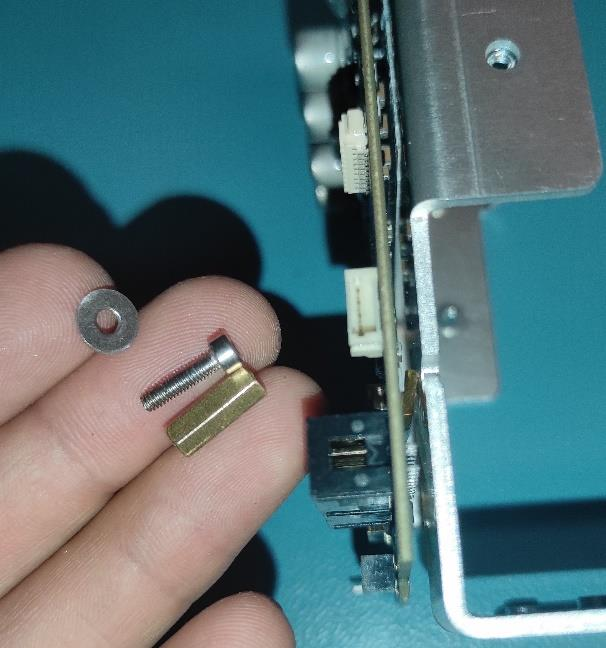

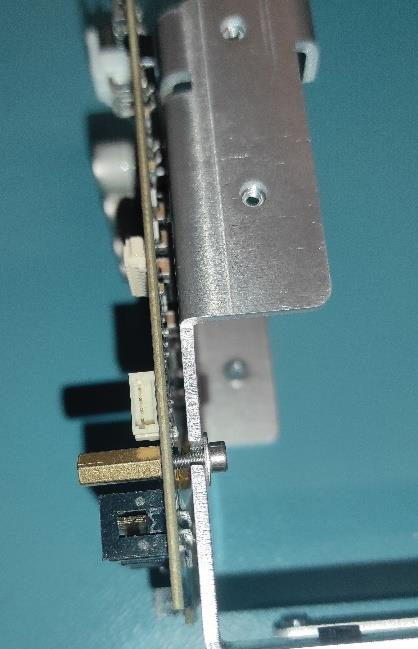

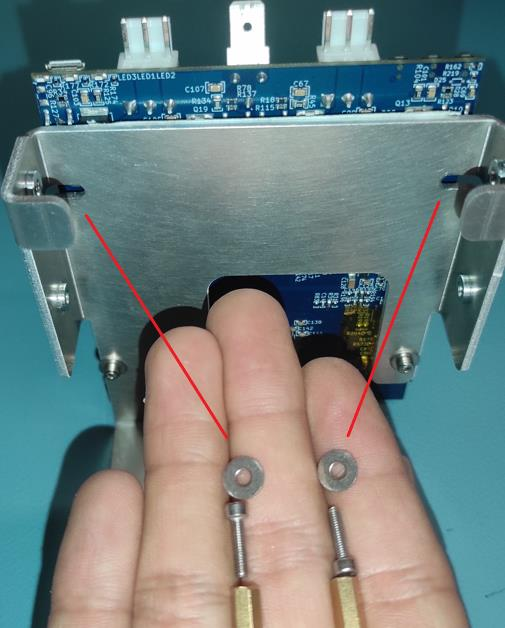

Use Spacer L=12 F_M2.5, WASHER 2.7, and BOLT M2.5x8 ((8.8) Zn) ISO 7380 to attach FIREWALL to PCB.

Warning

Do not tighten fully!

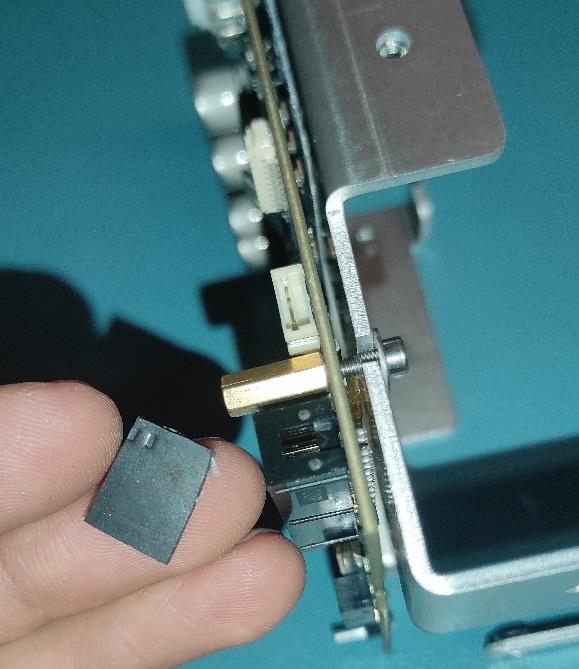

Add Rubber Pads

Place a 15x10x3 mm RUBBER PAD between FIREWALL and MOTOR BOARD at the PCB edge to ensure the components are parralele to one another. Tighten bolts gently with two-finger pressure. Repeat for the other side.

Note

The PCB and FIREWALL should be PARALLEL!

Secure Top Side of Firewall

Use SPACER L=12 F_M2.5, WASHER 2.7, and BOLT M2.5x8 ((8.8) Zn) ISO 7380 to gently tighten the top side of FIREWALL and PCB.

Important

Check that the components are in parralel to one another.

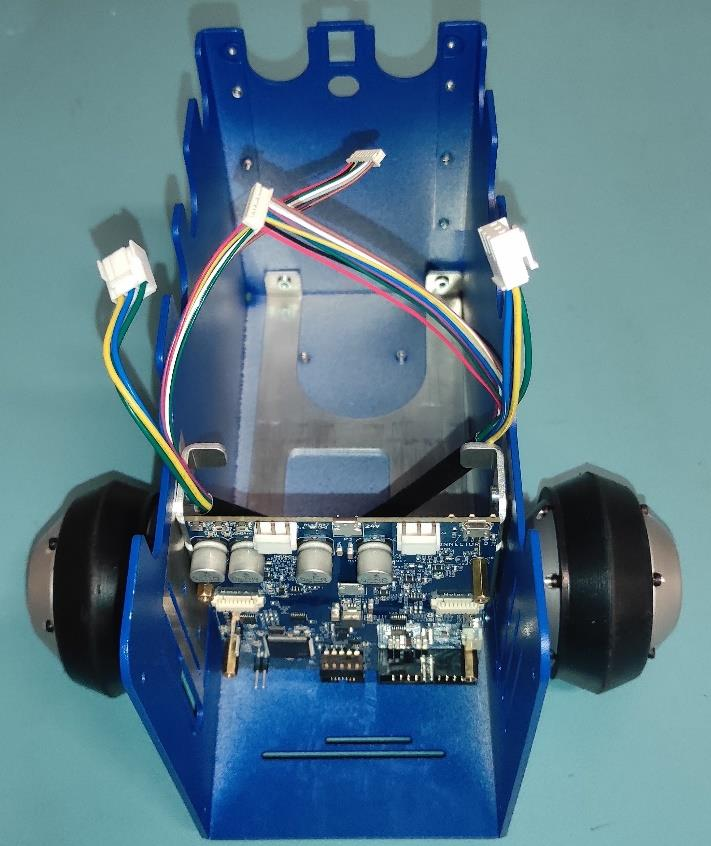

Install Firewall Assembly

Slide the FIREWALL assembly into the BASE.

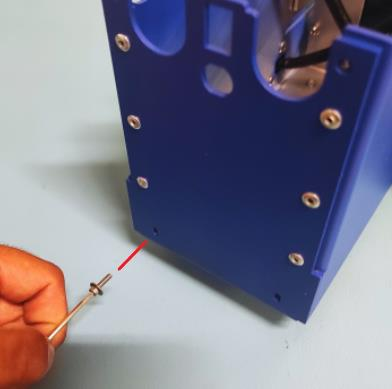

Secure Firewall Bottom

Use BOLT M2.5x8 ((8.8) Zn) ISO 7380, WASHER 2.7 to firmly tigthen the bottom of FIREWALL to BASE.

Secure Firewall Side

Use BOLT M2.5x8 ((8.8) Zn) ISO 7380, and WASHER 2.7. Thread lightly with an Allen key.

Note

Final tightening will be done after full assembly.

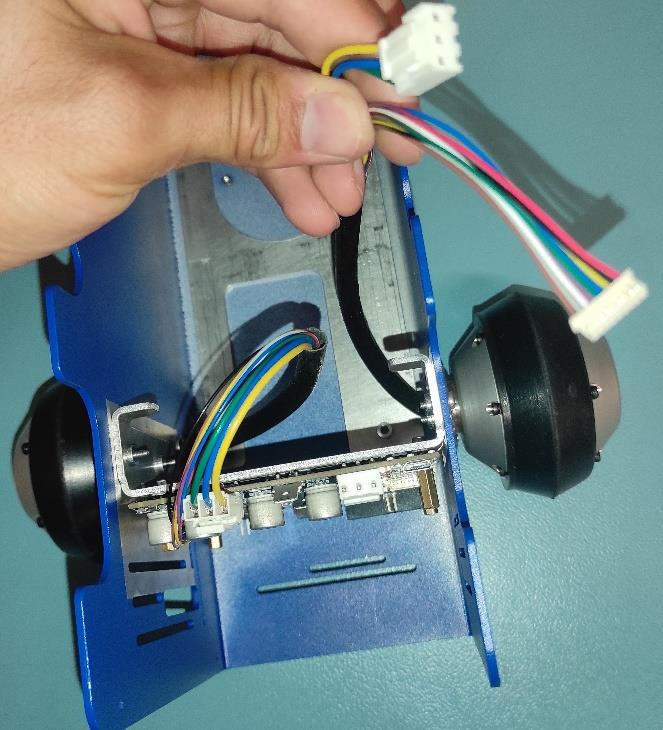

Connnect Left Motor Wheels

Attach the small left MOTOR WHEEL connector to the left side of the MOTOR BOARD. Be sure to turn it correctly.

Connect Large Left Motor Connector

Attach the large left MOTOR WHEEL connector to the MOTOR BOARD, orienting and routing the wire as shown.

Note

Left wheel connectors attach to the left side of the MOTOR BOARD. And the right wheel connectors to the right side.

Route Rigth Motor Wires

Ensure right-side wiring matches the pictures below.

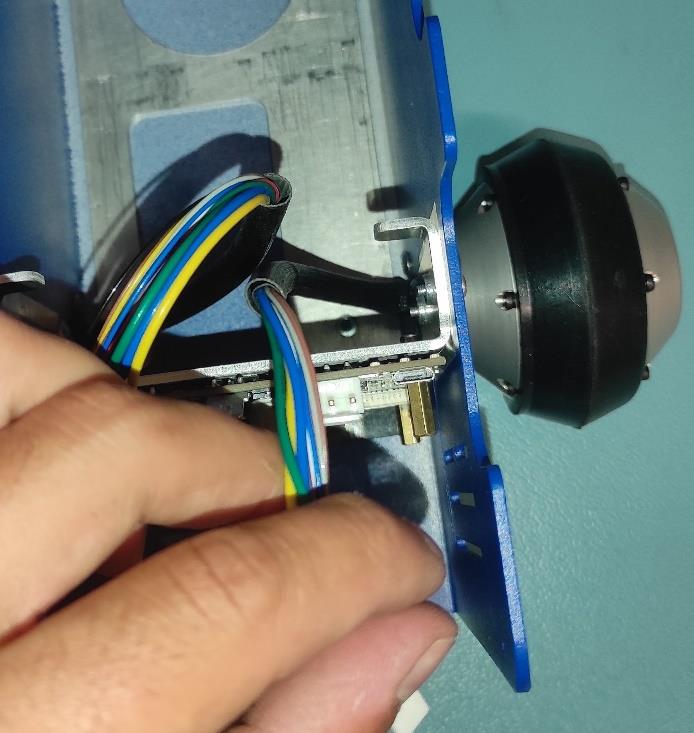

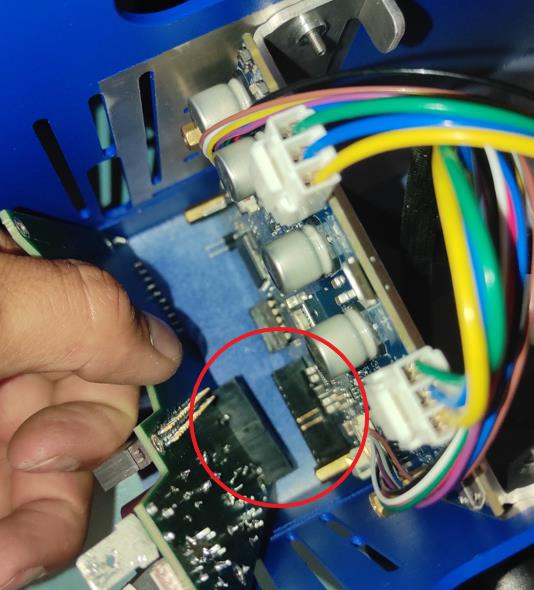

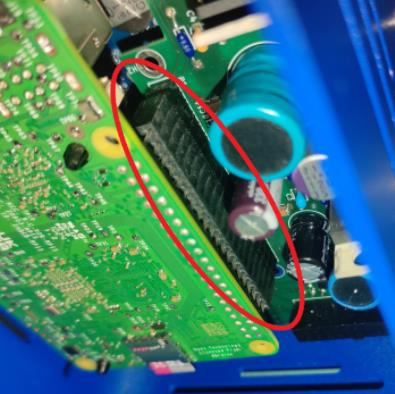

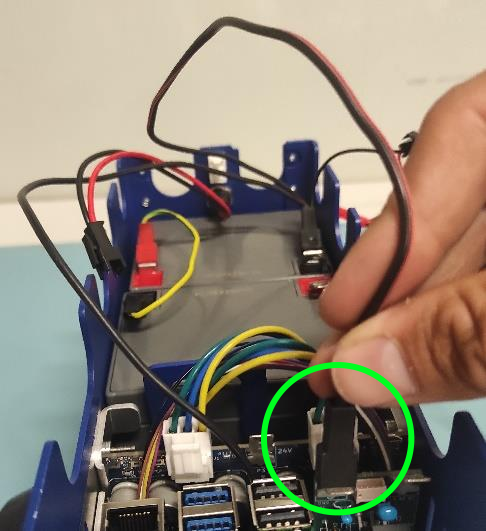

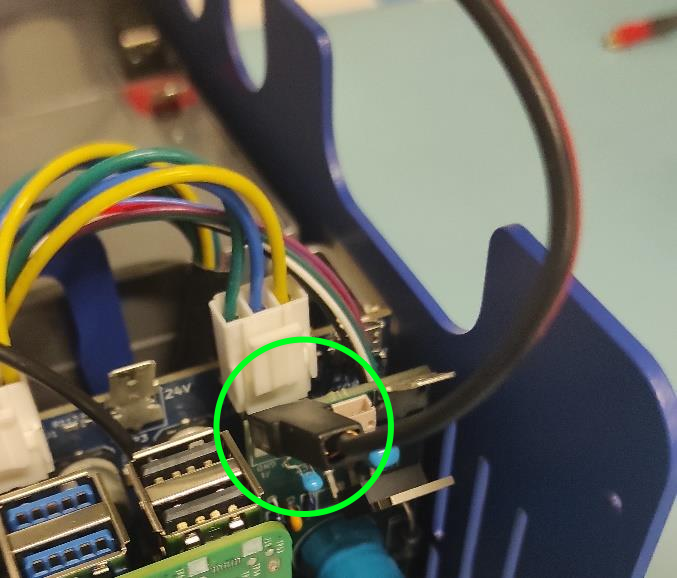

Connect Connection Board

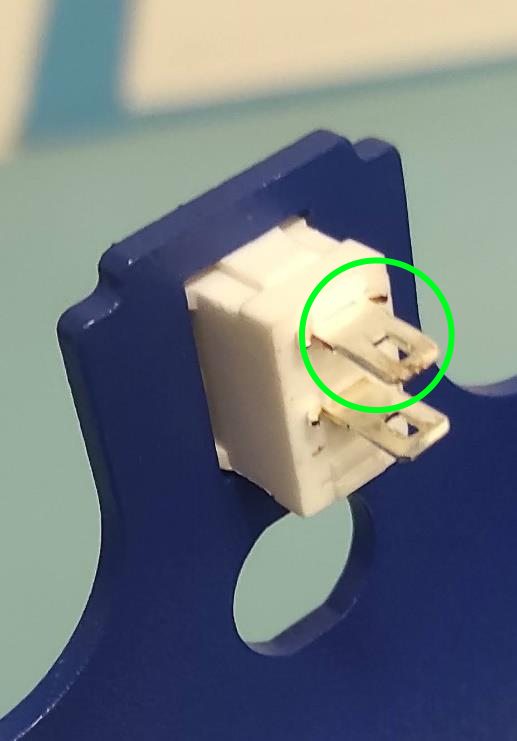

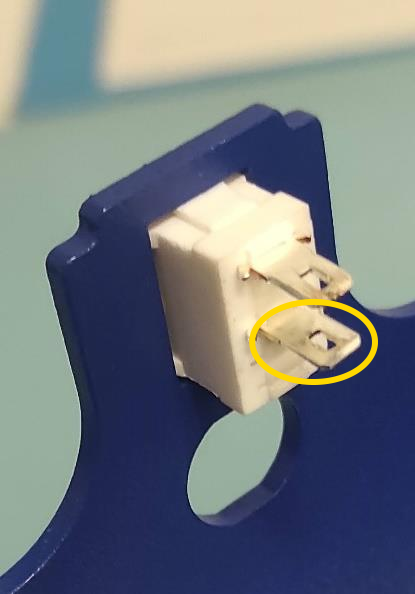

Gently push the CONNECTION BOARD connectors (red circle) into the MOTOR BOARD until fully engaged.

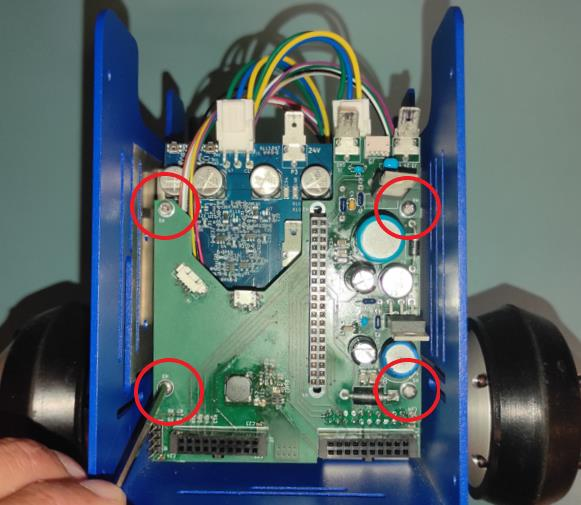

Secure Connection Board

Use 4x BOLT M2.5x8 ((8.8) Zn) ISO 7380 to fasten the CONNECTION BOARD to the MOTOR BOARD through standoffs.

Note

Tighten them carefully.

Connect Ground Wire

Attach the ground female spade crimp terminal from the wire harness to the ground pin on the MOTOR BOARD.

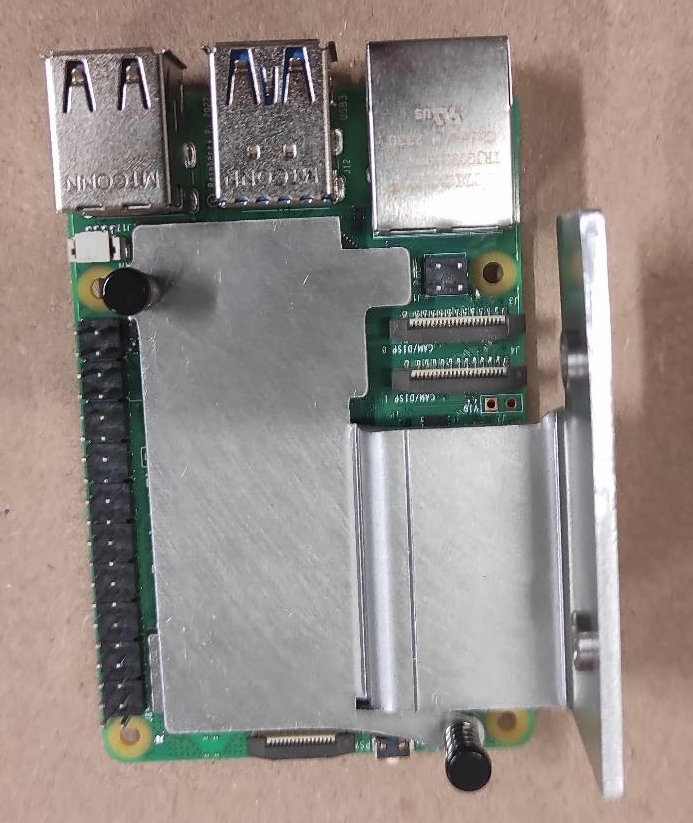

Prepare Rasbperr Pi 5

Cover the Raspberry Pi 5 CPU with double-sided thermally conductive tape and remove the protective film from the tape.

Gather Heatsink Components

Take HEATSINK, 2x PCB PUSH PIN WITH SPRING, and the previosly prepared Raspberry Pi 5.

Attach Heatsink

Position HEATSINK on Raspberry Pi 5 as shown in the picture and secure with 2x PCB PUSH PINS WITH SPRING.

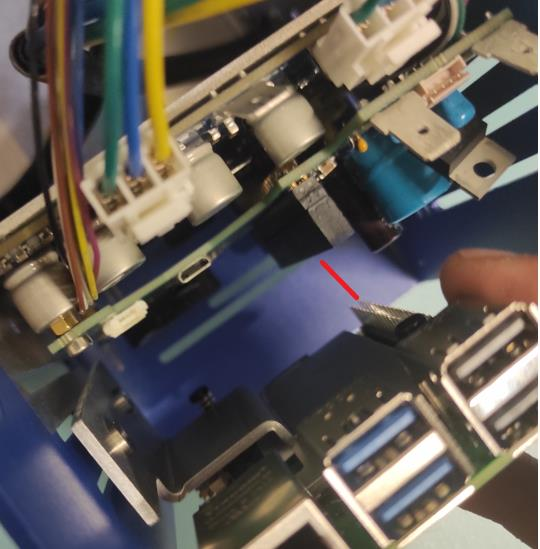

Connect Raspberry Pi to Connection Board

Connect the Raspberry Pi HAT & GRIPO INTERFACE connector together with CONNECTION BOARD as shown in the picture.

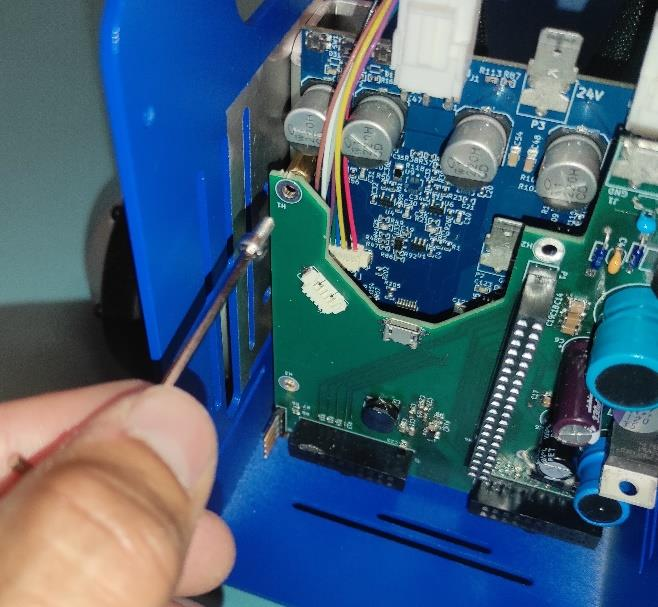

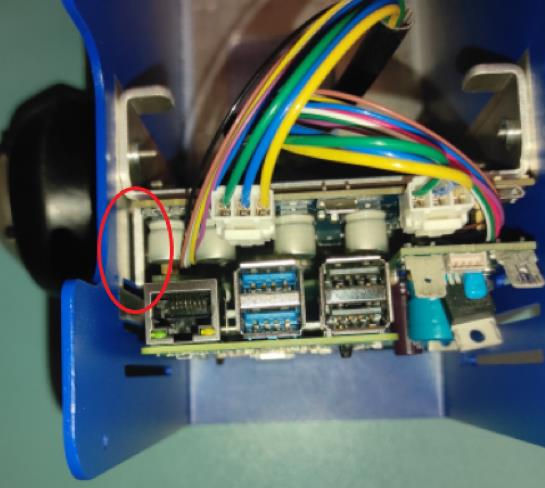

Secure Raspberry Pi (Part 1)

Ensure the HEATSINK contacts the BASE metal sheet and USB/Ethernet ports are accesible. Use 1x BOLT M2.5x8 ((8.8) Zn) ISO 7380 with WASHER 2.7 and tigthen gently.

Warning

Do not tighten the screw fully.

Secure Raspberry Pi (Part 2)

Insert another BOLT M2.5x8 ((8.8) Zn) ISO 7380 with WASHER 2.7. Press Raspberry Pi 5 to center USB/Ethernet ports in the slot, then tigthen gently.

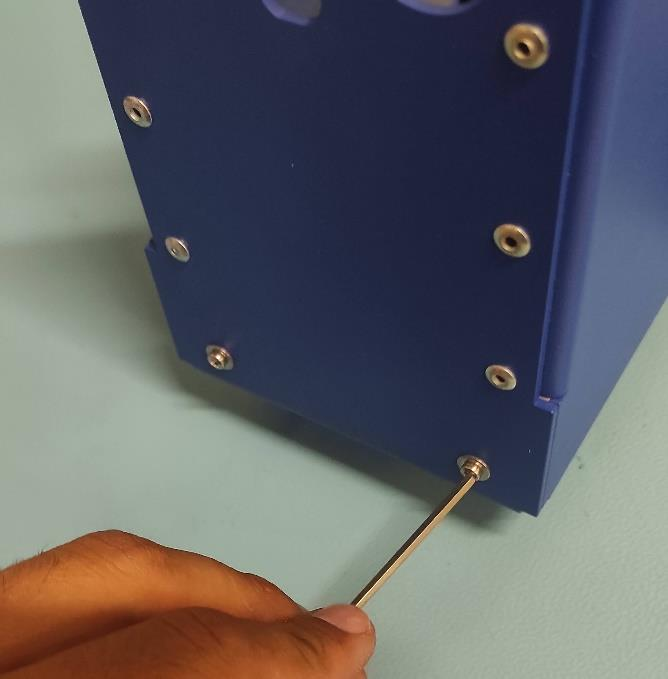

Secure Firewal Bottom

Use 2x BOLT M2.5x8 ((8.8) Zn) ISO 7380 with WASHER 2.7 to fasten FIREWALL to BASE at the bottom of the robot.

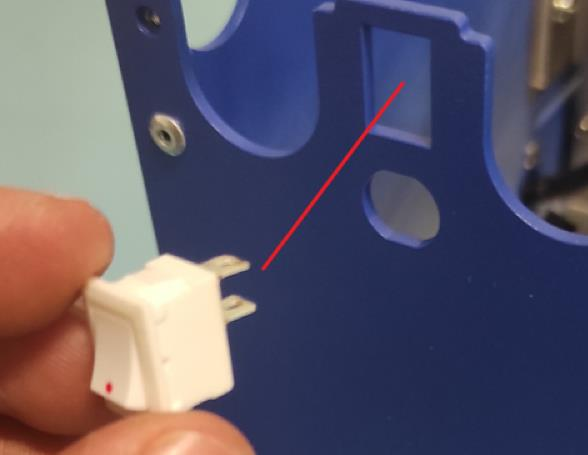

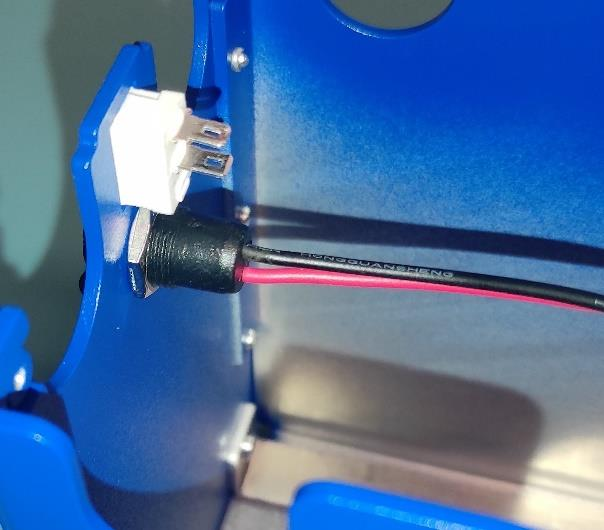

Install On/Off Switch

Press the ON/OFF ROCKER SWITCH into the slot. Make sure you follow the picture bellow.

Important

Pay attention to the position of the dot on the switch. The dot needs to be on the bottom.

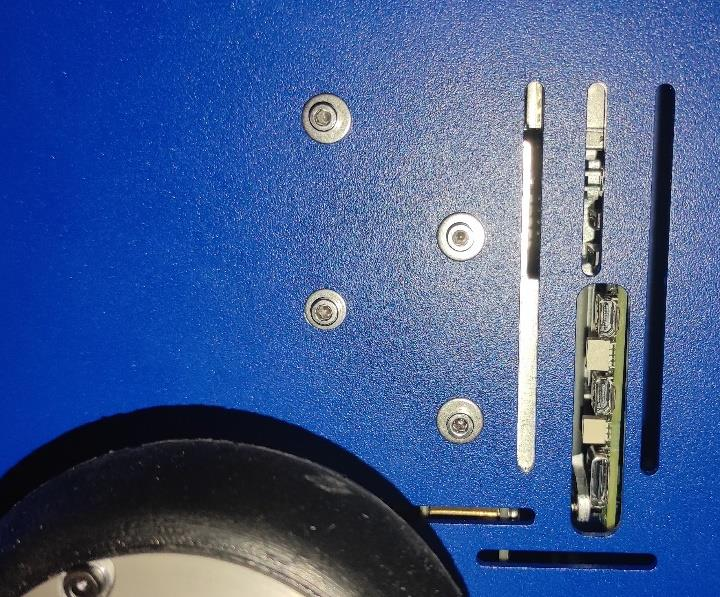

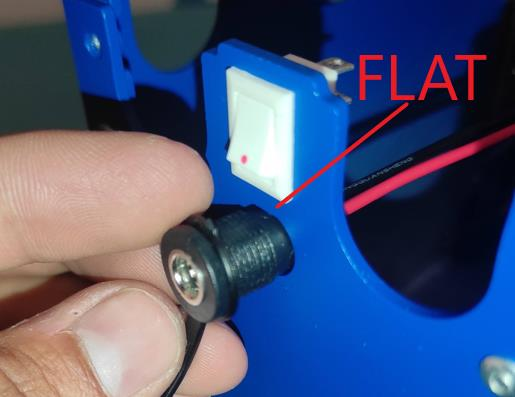

Install DC Power Charger

Push the 5.5 x 2.1 mm DC POWER CHARGER through the opening as shown in the picture below.

Align DC Charger

Align the first flat part of the charger with the slot and push through the sheet metal as shown in the picture below.

Secure DC Charger

Attach the nut to the charger connector.

Tighten DC Charger

Ensure that the connector is properly aligned as shown in the picture. Then hand-tighten the nut.

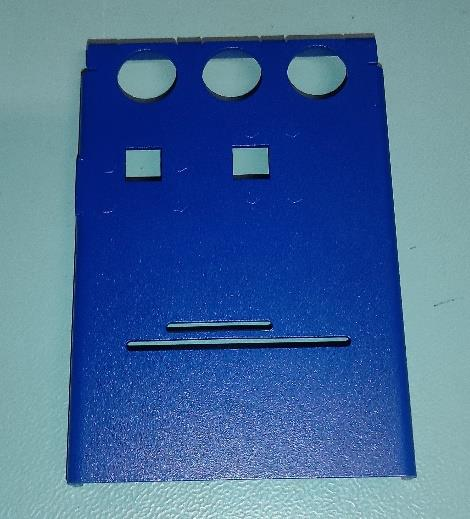

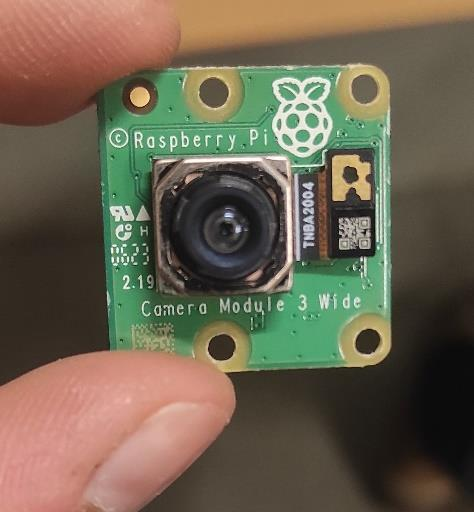

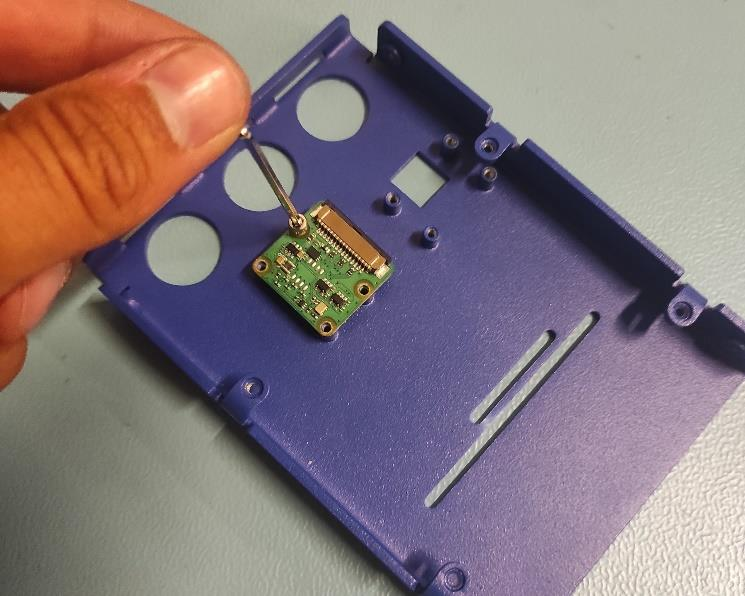

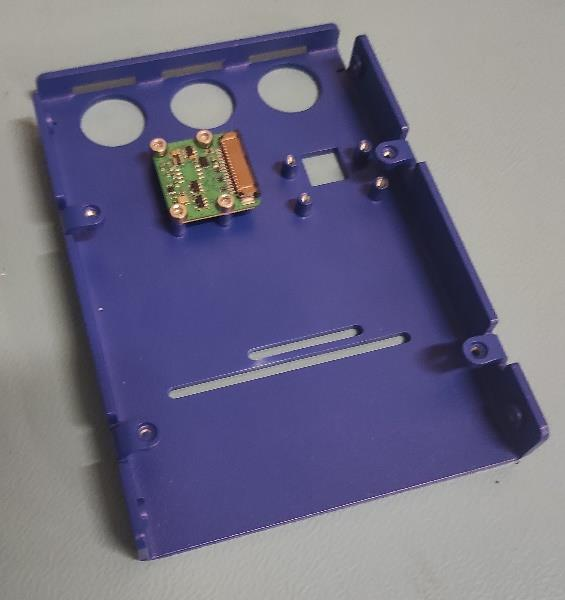

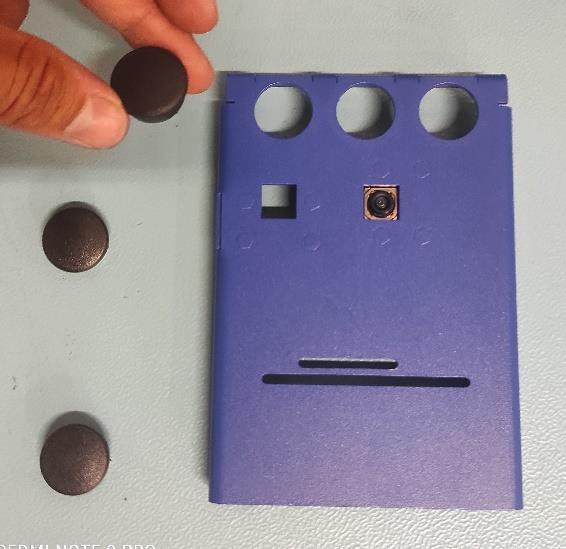

Prepare Front Hatch

Take FRONT COVER of the Robot and CAMERA 3 WIDE.

Attach Camera to Front Cover

Use 4x BOLT M2.5 ((8.8) Zn) ISO 7380 to secure the CAMERA to the FRONT COVER. Tigthen with Allen key using two-finger pressure.

(OPTIONAL) Second Camera

Use 4x BOLT M2.5 ((8.8) Zn) ISO 7380 to attach a second CAMERA to the FRONT COVER, tigthening with two-finger pressure. The robot ships with one camera. You may add a second or reposition the first for a different angle.

Install Cover Caps on Front

Press COVER CAPS firmly into the FRONT COVER by hand.

Tip

Use steady hand pressure to secure the caps.

Warning

Try to avoid pinching your fingers while pressing the caps. As this may lead to some pain.

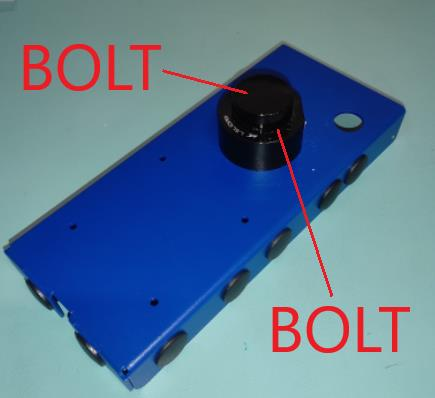

Preparing Top Cover and LIDAR

Just like for the FRONT COVER, insert COVER CAPS into the TOP COVER. Secure LIDAR to the TOP COVER with 2x BOLT M2x14 (8.8 Zn) ISO 7380, tigthening gently with two-figer pressure.

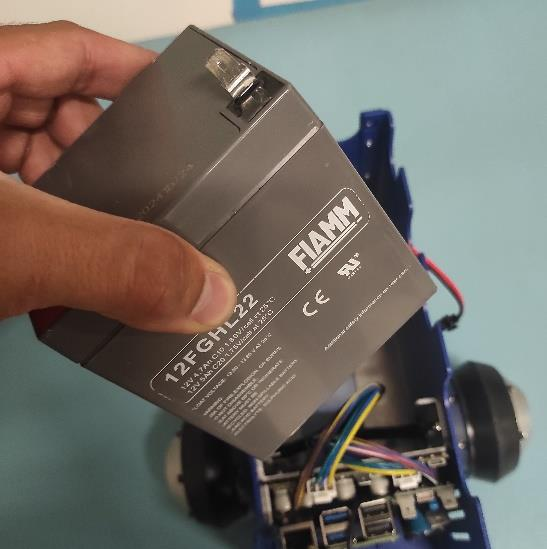

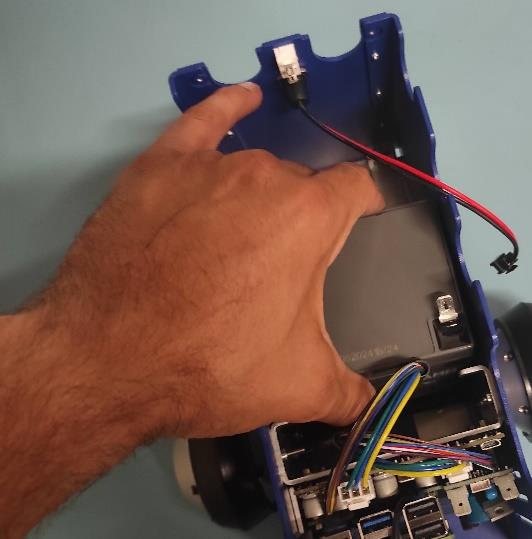

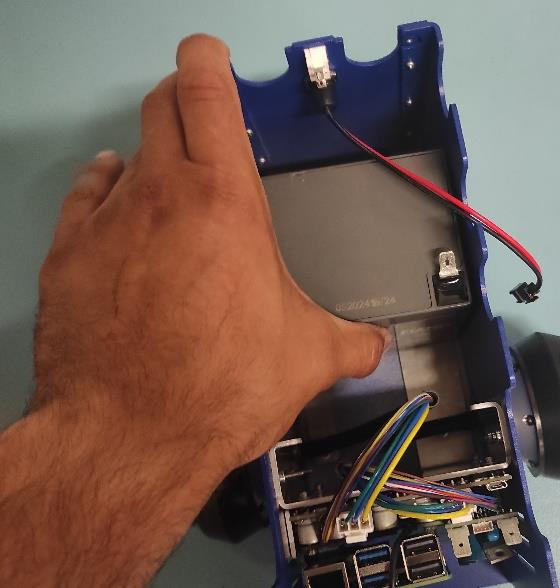

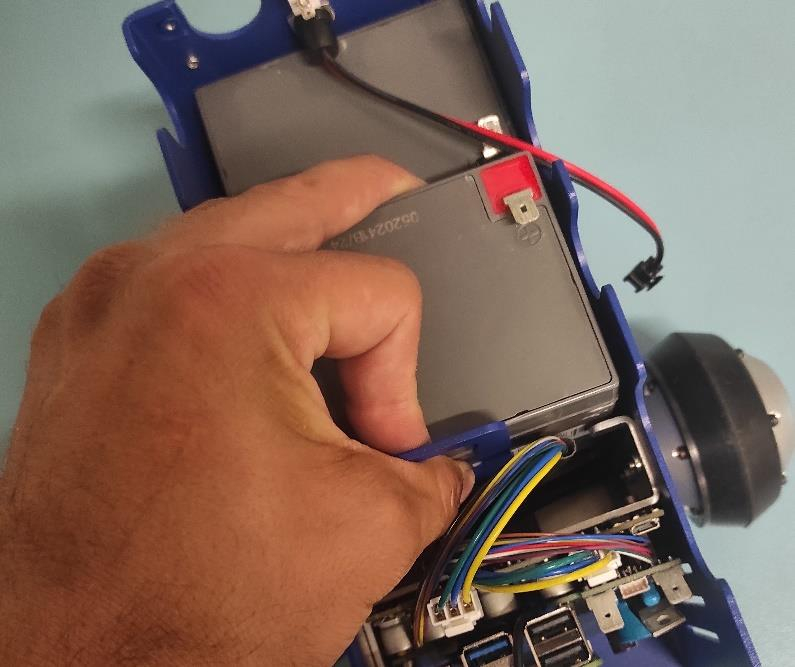

Install First Battery

Position the first BATTERY in the BASE according to the pictures below. Pay close attention to its orientation.

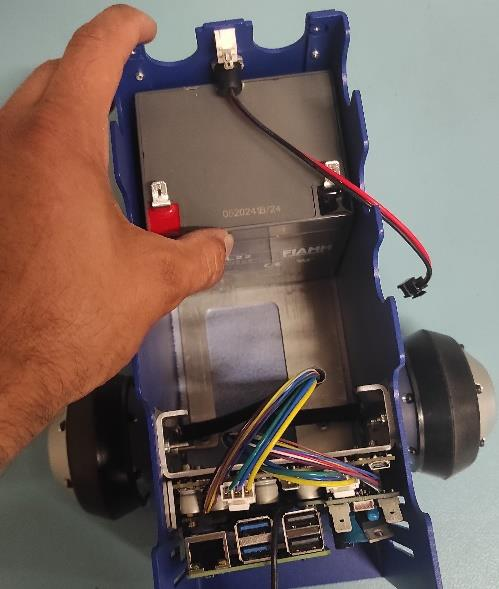

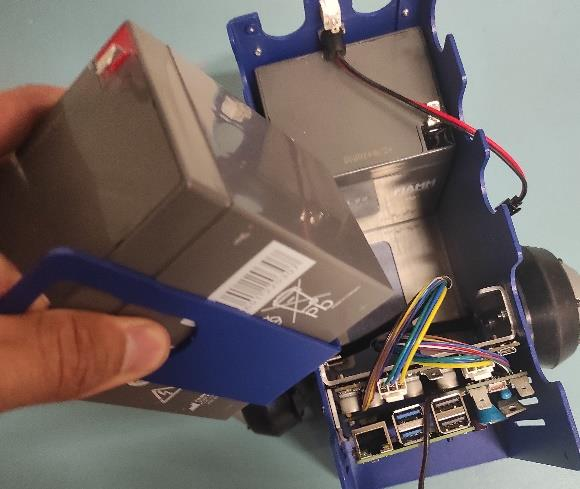

Install Second Battery

Use the BATTERY HOLDER to secure the second BATTERY in the BASE as shown in the picture.

Properly Adding the Second Battery

Be careful with the wires.

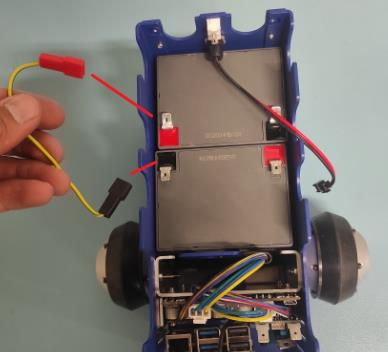

Connect Batteries in Series

Attach the yellow-green wire: red connector to the RED spade of the first battery, black connector to the BLACK spade of the second battery.

Note

Red connector from the wire goes to the RED spade of the first battery. Black connector of the wire goes to the black spade of the second battery.

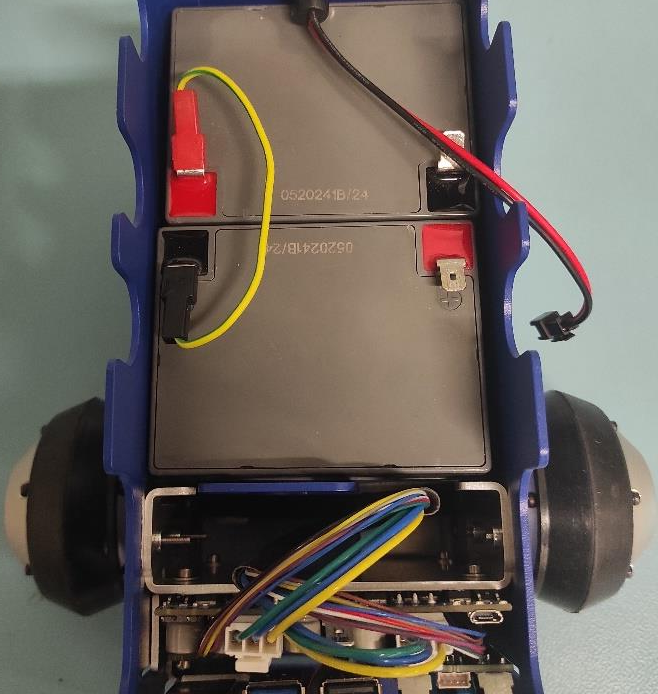

Connect Black Spade to Battery

Take the wire harness and connect the black female spade terminal to the negative battery pin as shown in the picture. Press it in firmly.

Connect Black Spade to Ground

Grab the only free black female spade connector and attach it to the GND pin on the CONNECTOR BOARD as shown in the picture.

Connect Red Spade and Charger

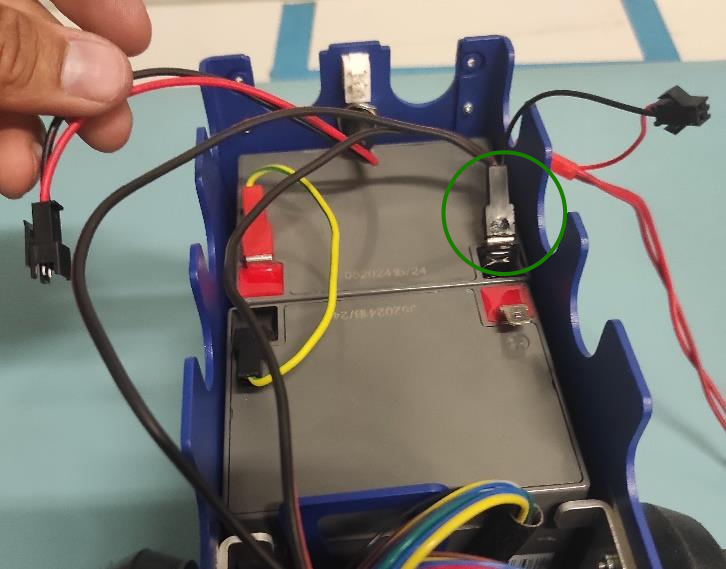

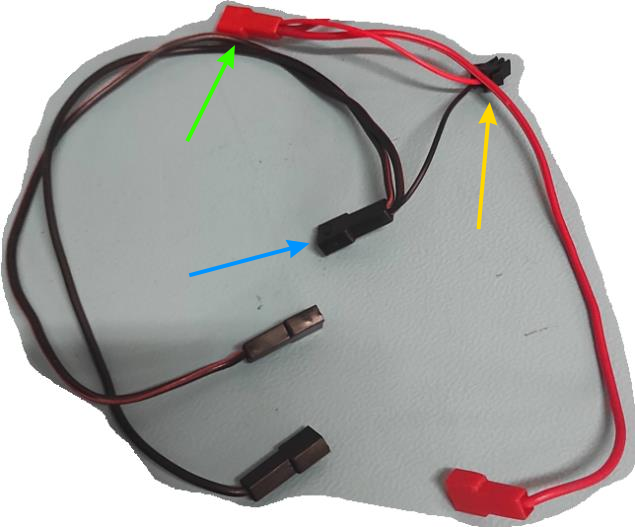

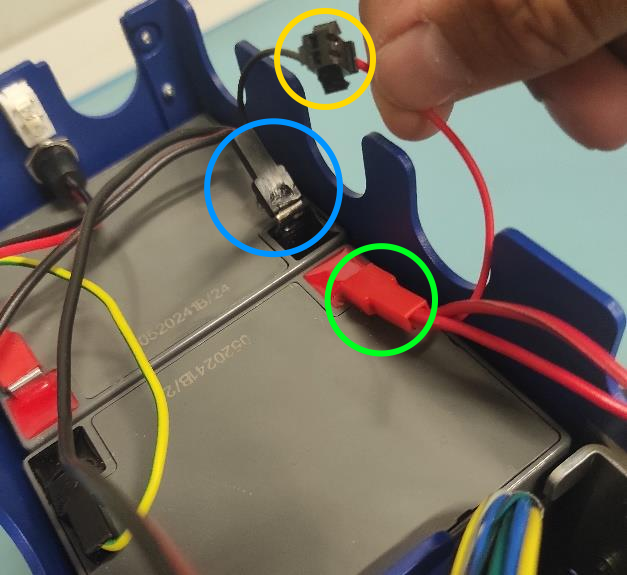

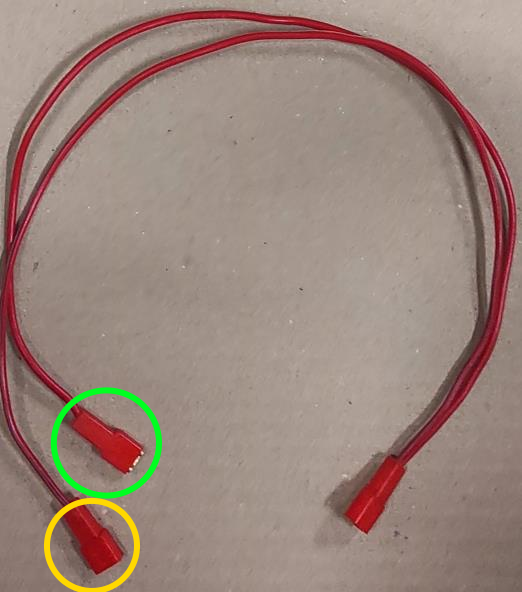

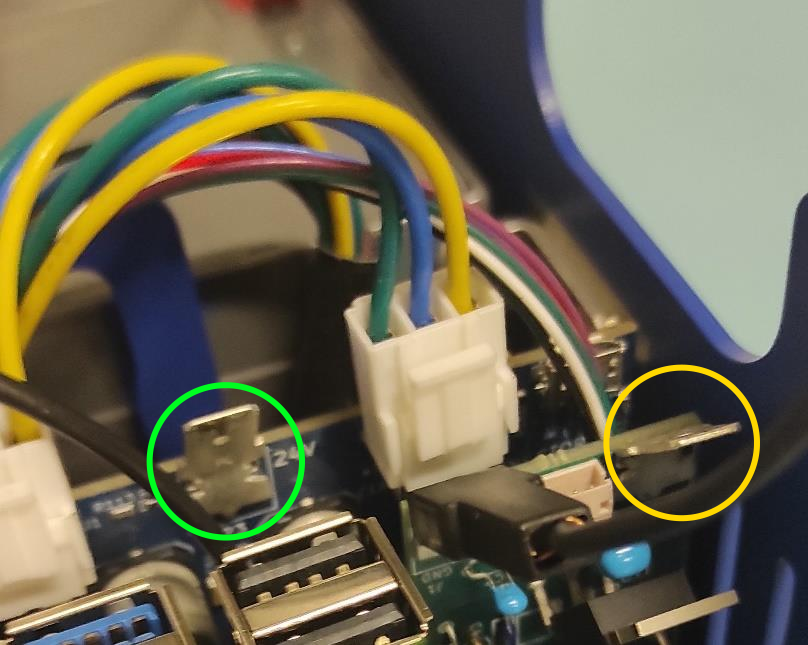

Attach the short RED spade connector to the positive battery pin (green circle). Connect the charger connector to the 5.5 x 2.1 mm DC POWER CHARGER (yellow circle). Finally connect the BLACK spade connector to the negative spade of the first battery (blue circle).

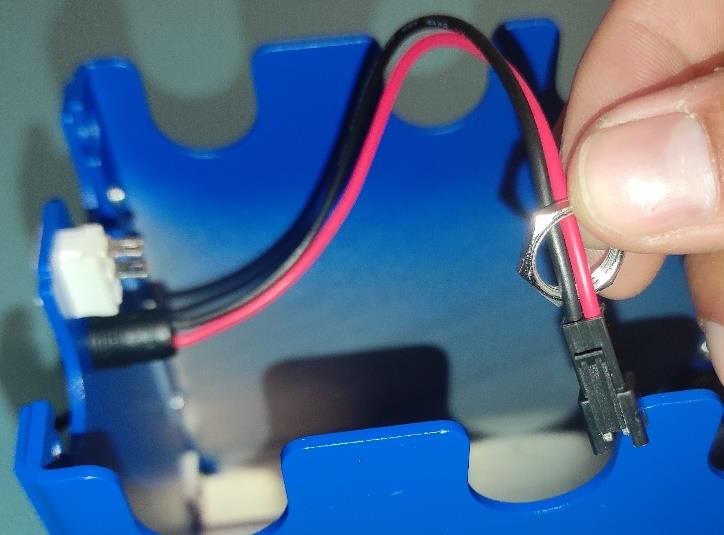

Connect Red Spade to Switch

Attach the remaining red spade connector to the upper pin of the ON/OFF switch.

Connect Second Wire Harness

Use the wire harness with 3 red spade connectors. Attach the split connector (yellow circle) to the bottom pin of the ON/OFF SWITCH.

Connect Remaining Spade Connectors

Attach on red spade connector to the 12V pin on the CONNECTION BOARD and the other to the 12V pin on the MOTOR BOARD.

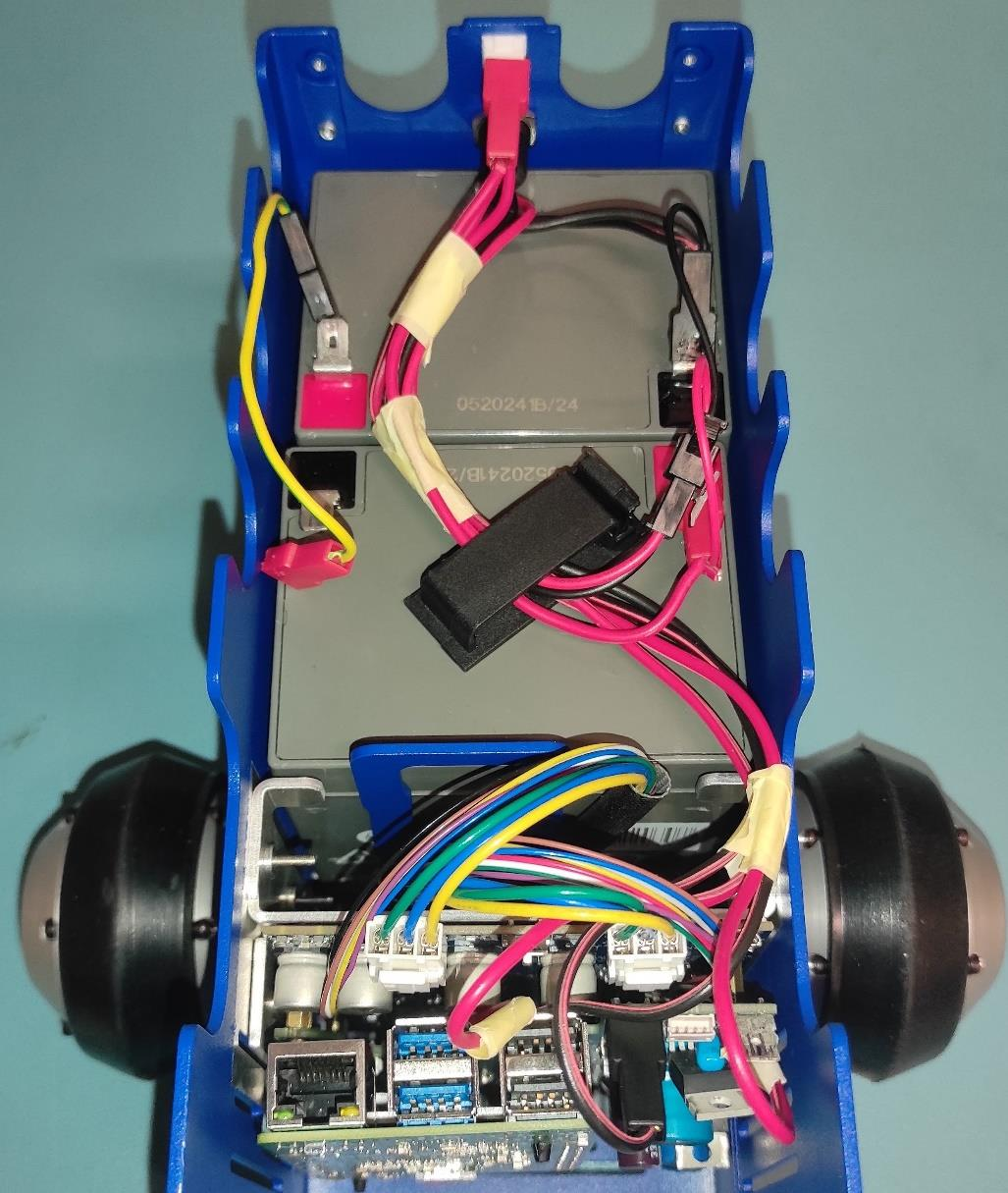

Verify Wiring

Ensure all spade connectors are firmly attached. Route wires as shown.

Important

Double-check that all connections (all pins are firmly connected).

Note

UPDATE of the WIRE ROUTING is coming soon.

[TODO: Add image here without the wires being taped/secured to the second battery.]

Attach Top and Front Covers

Position TOP COVER and FRONT COVER. Use 2x BOLT M2.5x10 ((8.8) Zn) ISO 7380 with washers, tigthening with two-finger pressure. Fully tigthen with an Allen key once aligned.

Secure Front Cover Bottom

Use BOLT M2.5x8 ((8.8) Zn) ISO 7380 with WASHER 2.7 to tigthen the bottom of the FRONT COVER with two-finger pressure.

(OPTIONAL) Top Cover Securing

Use BOLT M2.5x8 ((8.8) Zn) ISO 7380with WASHER 2.7 to secure the TOP COVER. Tigthen lightly with two-finger pressure. This step is optional

Note

This step is optional, as the cover’s weight may be enough to keep itself shut.

Tip

If you are opening and closing the TOP COVER repeatedly then we suggest to avoid this step.

[ FIXME: This should be secured from the other side. I think. ]